Hello, my name is Hans Chen, technical sales manager at CFM. Today I’m showing you our Entry-Level Bar product Flow Wrap Solution.

For some small bar manufacturers or startups, it’s a really cost-effective choice.

This solution allows them to quickly increase the packaging efficiency at a surprising price.

Also, it can grow alongside your company to pack different sizes of new products in the future.

That is our C-F1 series Entry-Level bar flow wrapper. We have some specific designs for bar products on this machine.

-Full 304 stainless steel machine body

-Up to 4 hand feed working positions

-Food-grade plastic pusher pins and feeding channel

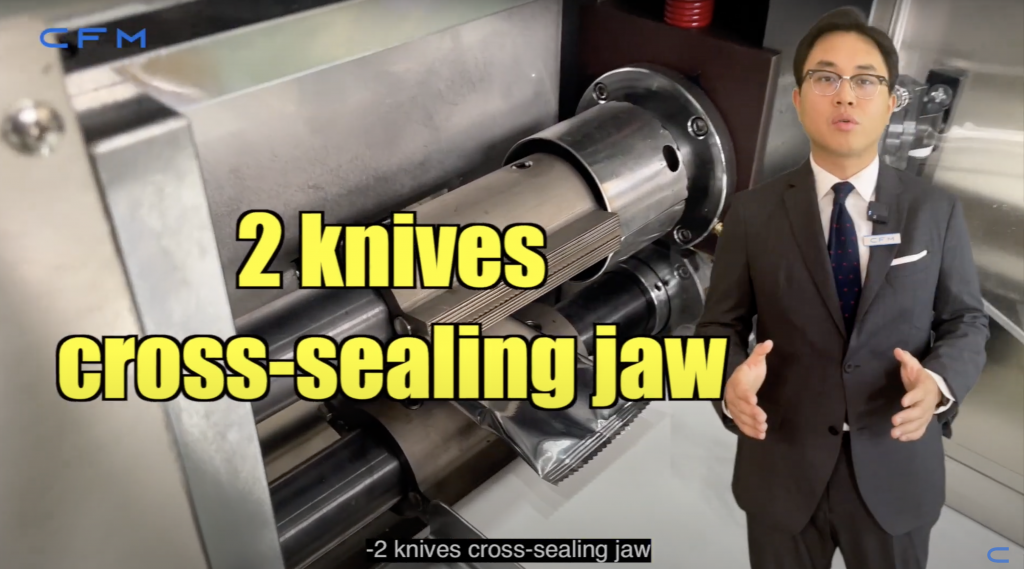

-2 knives cross-sealing jaw

-discharge belt and safety cover

-metal machine stand and moveable wheels

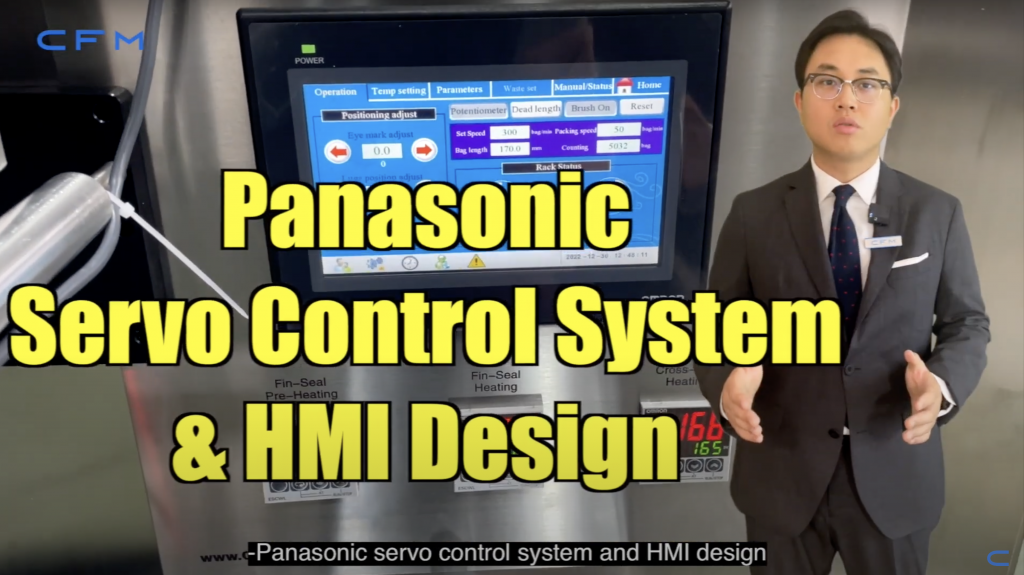

-Panasonic servo control system and HMI design

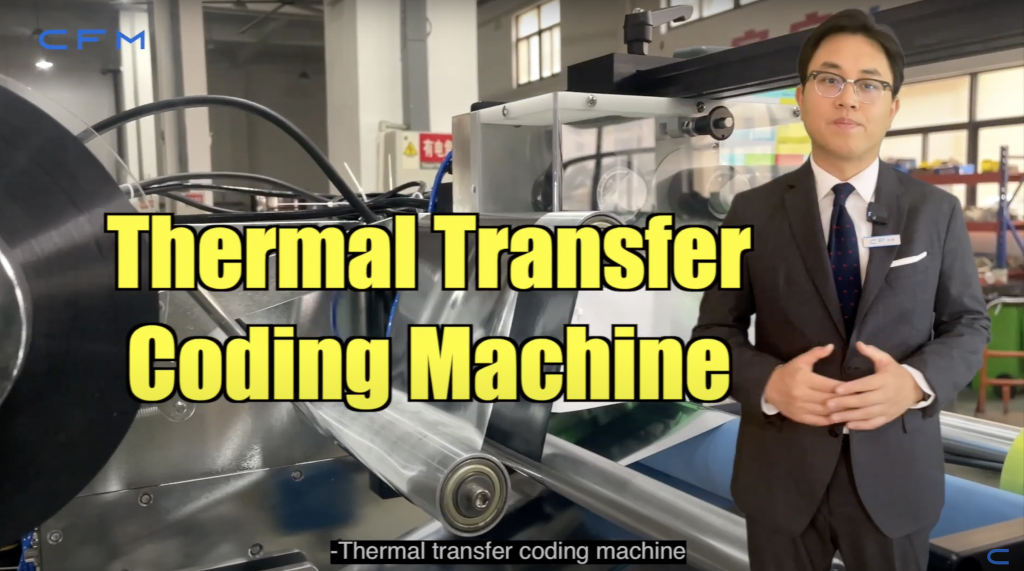

-Thermal transfer coding machine

Etc

Here, I’d like to highlight 2 features

-Food-grade plastic pusher pins and feeding channel

&

-Panasonic servo control system and HMI design

For Food-grade plastic pusher pins and feeding channels, it is a specific design for some sticky products, like some candy bars or nutrition bars, which are made from natural ingredients.

This food-grade plastic material can maximally decrease the product sticking to the feeding channel, and the easy clean feature of this material can avoid cross-contamination with some allergen-free products.

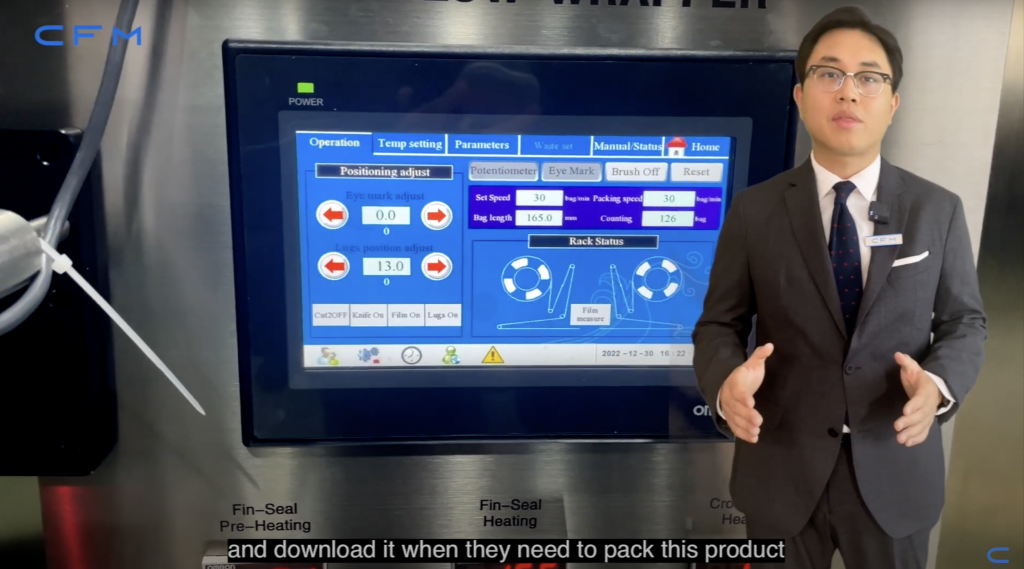

For the Panasonic servo control system and HMI design, it is the key to fast changeover for different sizes of products.

The operator only needs to simply adjust some packaging parameters in the HMI, like package length, feed position, and some mechanical parts, then the machine can automatically change and adapt to different sizes of products. It takes only 5 minutes for some skilled operators.

After each setup, the operator only needs to store the recipe in the program, and download it when they need to pack this product. The machine will be reset to the relative parameters without repeating the operation.

Our design speed for this solution is up to 200 packs per minute. That’s the limitation of hand load speed.

As long as the machine gets enough hand load speed, the packaging speed could get faster.

This is a very mature entry-level bar flow wrap solution that has been proven in the marketplace and we have taken all the operating experience and machine stability to an unprecedented level.

If you are interested in this machine, please feel free to contact us, and we may be able to book you a visit to a local machine.

Thank you for watching and see you next time!