Hey! Do you know how to pick the best chocolate flow wrapper, if you are a chocolate products manufacturer, you may have questions, let’s find it out.

My name is Hans, technical sales manager at CFM.

For this question, firstly we need to define what speed you are looking for.

Speed less than 150 pcs/min

If you are looking for a chocolate flow wrapper that a speed is less than 150 pcs/min, then a semi-automated entry-level flow wrapper is a good choice.

It can dramatically improve packaging efficiency compared to manual packaging, and it is really a cost-effective choice.

Also, most chocolate manufacturers do not only produce 1 size of the chocolate, so they need to pack a variety of sizes of chocolates on 1 machine, which calls for a fast changeover function for different sizes of chocolate on the same machine.

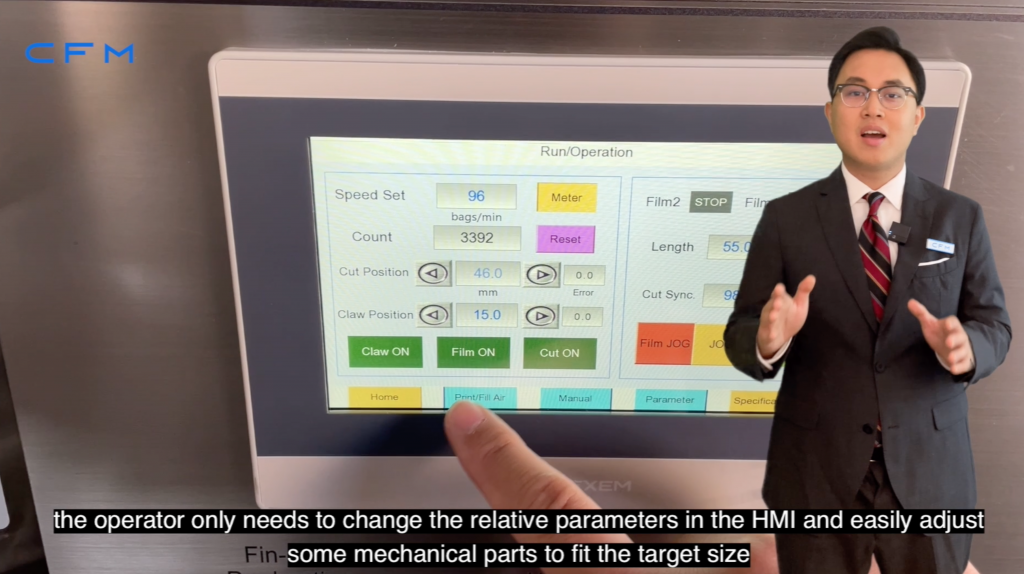

The servo control technology could bring this changeover experience to a senseless level, the operator only needs to change the relative parameters in the HMI and easily adjust some mechanical parts to fit the target size, then it works.

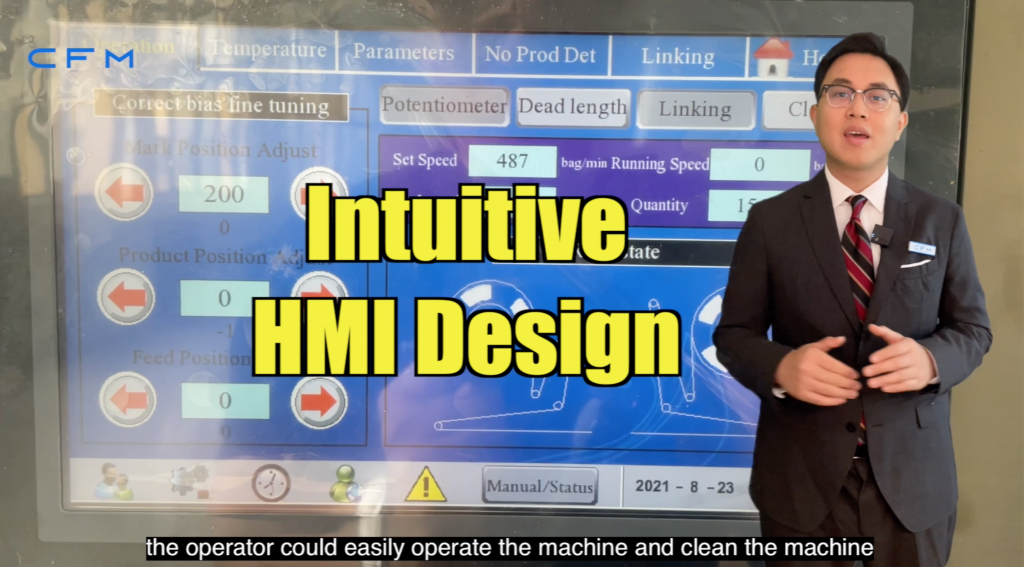

Our C-F1 flow wrapper is 1 of the optimal choice to fit this packaging needs. Full-stainless steel construction, small footprint, 3 Panasonic servo motors control system, intuitive HMI design.

We created this machine all based on the best user experiences direction, generally, we have completed the commissioning before delivery, and the machine can work for customers right away as soon as they receive it, even when they had no experience with a flow wrapper.

We will send engineers to customer’s factories to help them set up the machine, and train the operating skills

During the pandemic, we provide virtual technical services, For some areas, we provide technical services locally, and fast troubleshooting reaction and spare parts support are important parts of our after-services.

So in conclusion for low-speed packaging needs, an entry-level flow wrapper is a good choice for some small chocolate manufacturers or Startups, it brings a perfect user experience at a small cost,

Also in some cases, it can grow alongside your company, for some particular products, we can add an automated infeed system in the future, to further increase the packaging efficiency.

Speed more than 200 or 300 pcs/min

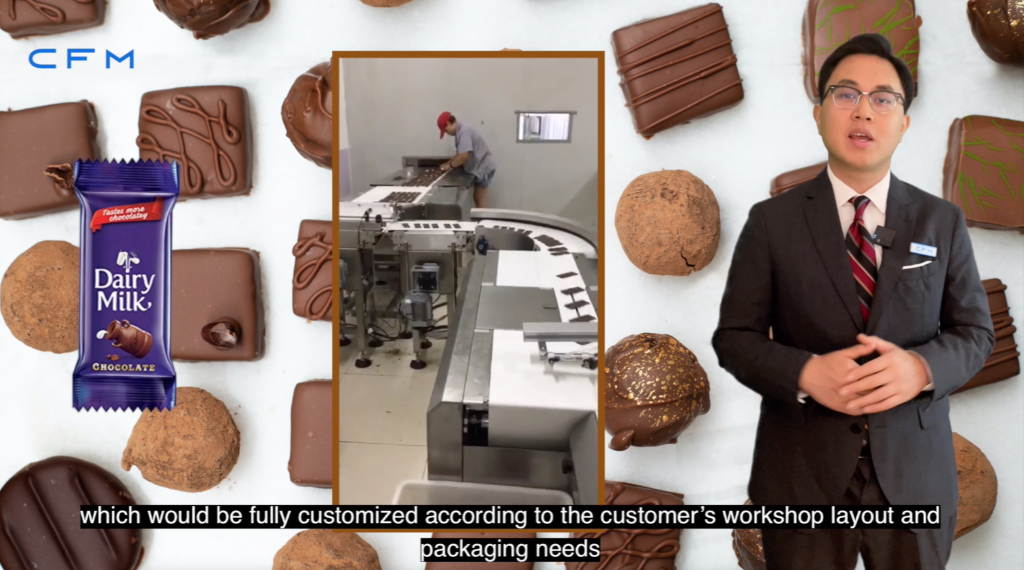

But if you are looking for a chocolate flow wrapper that a speed is more than 200 or 300 pcs/min, then a fully automated flow wrapper is necessary.

In this case, normally customers have a big capacity for single-size chocolate, in order to maximize the packaging efficiency, the flow wrapper will be connected to the production line directly through the transfer belts, which would be fully customized according to the customer’s workshop layout and packaging needs.

This solution can maximize efficiency, minimize labor costs and barely require human intervention, this feature could bring a great hygienic condition to the chocolate products, especially for some Allergen-FREE products, it is a critical feature to keep the product clean.

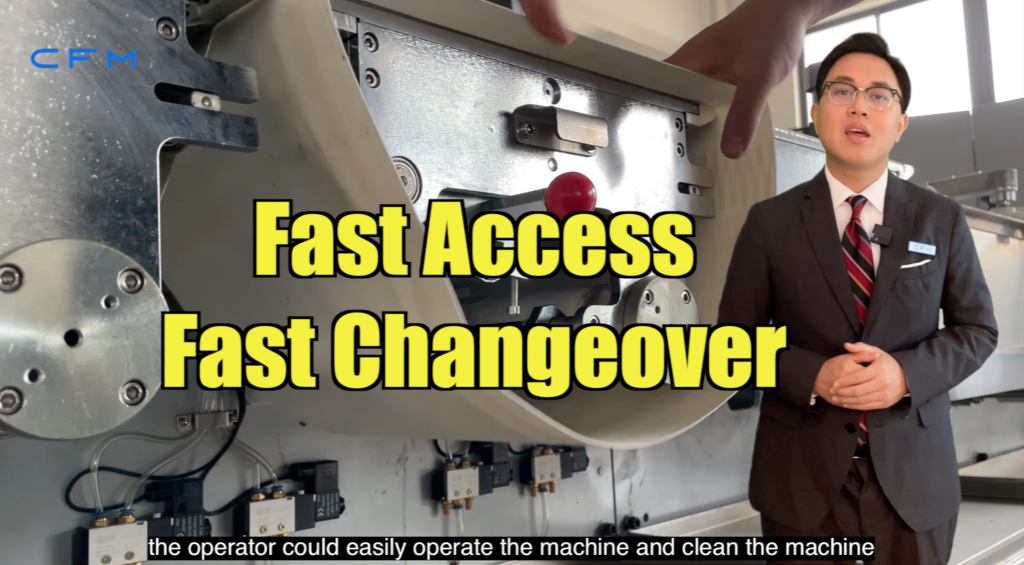

Also for some chocolate products contract manufacturers, the fast changeover is an important feature to help them handle the different packaging requirements of their customers, it should be as easy as possible to switch from 1 size of chocolate to another.

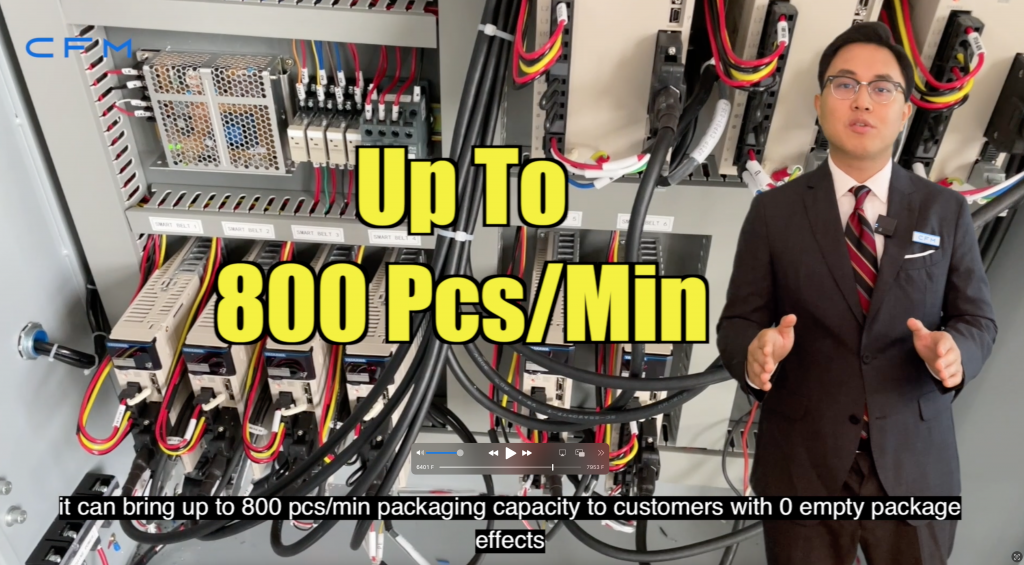

Our C-F10 flow wrapper is designed for High Efficiency, High capacity flow wrap packaging needs, thanks to the 9 Yaskawa servo motors control system, it can bring up to 800 pcs/min packaging capacity to customers with 0 empty package effects.

Also with the amazing Fast-access, Fast-changeover design, and Intuitive HMI design, the operator could easily operate the machine and clean the machine, as well as easy to switch 1 size product to another.

In conclusion for high-speed packaging needs, a fully-automated flow wrapper is a good choice for some middle to big-size manufacturers,

it can maximize packaging efficiency and minimize machine downtime, as well as bring a great hygienic condition to the products.

Well, that is today’s proposal based on our years of experience in the flow wrappers field, If you have any packaging needs, please feel free to let us know, thank you and see you next time.

Hans’ Email: 1@CyberFoodMachine.com

Hans’ WhatsApp: +1 (978) 219 2826