Flow wrap is 1 of the most popular packaging solutions for packaging products like food, candy bars, confectioneries, and bakery products.

Maintaining your flow wrapper is very important to keep it running smoothly and efficiently at high speeds and with high accuracy packaging effect.

If you don’t properly maintain your flow wrapper, you could end up with decreased production, downtime, or even cause the seal flow wrappers damaged in the facility.

In this blog post, we will discuss some tips and tricks to help you maintain your flow wrapper to benefit your packaging tasks in the future and improve the packaging solutions’ efficiency.

1. Clean your horizontal flow wrapper regularly

If you want to keep your flow wrapping machine running smoothly, it is important to keep the flow wrapping machine area clean and free of debris.

Any buildup of dust or dirt can cause problems with moving parts, so it’s best to keep it as clean as possible.

A quick wipe down with a damp cloth once a week is sufficient, but if there is a lot of dirt around the machine, you may need to do a more thorough cleaning.

It’s also important to keep an eye on the seals of your packer to make sure they’re free of debris. If you see any buildup, simply use a soft cloth or brush to clean it off.

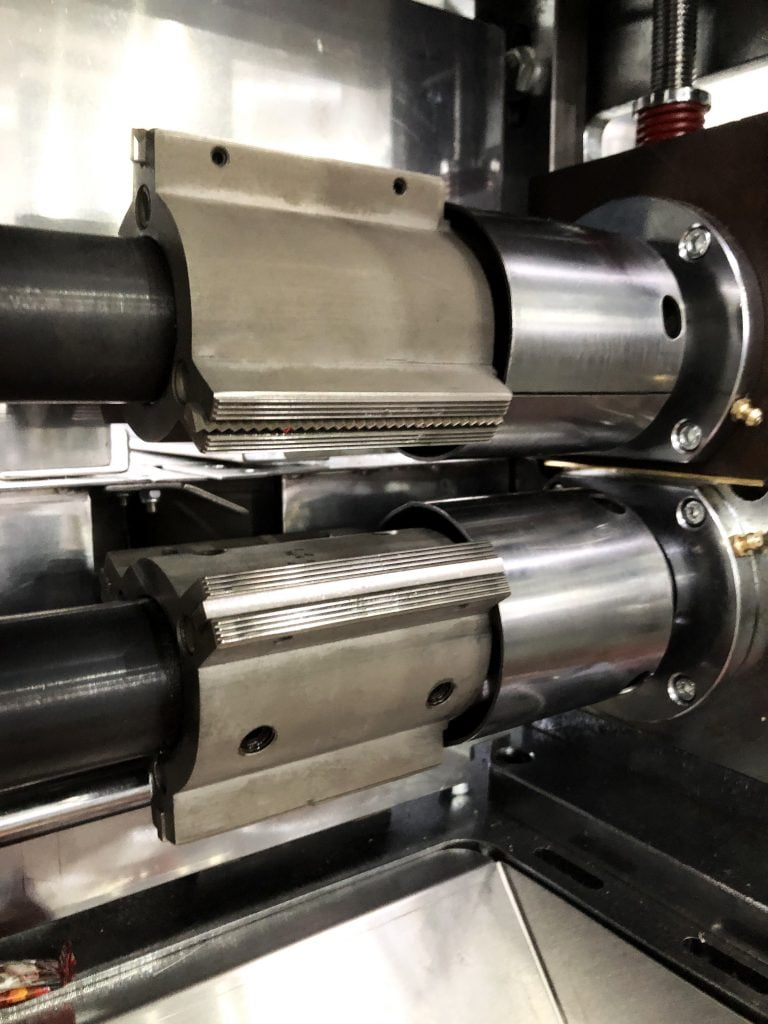

2. Check the horizontal flow wrapper seals regularly

One of the most important aspects of maintaining your flow wrapper is to regularly check the sealing components of the wrapper.

These sealing components are key to ensuring the machine produces perfectly sealed packages, so it’s important to make sure they are in good condition.

If you see any cracks or damage, it’s a good idea to replace the seal parts. You can ask your machine supplier for a replacement seal, or if this is a generic part, then you can buy a replacement part locally to use.

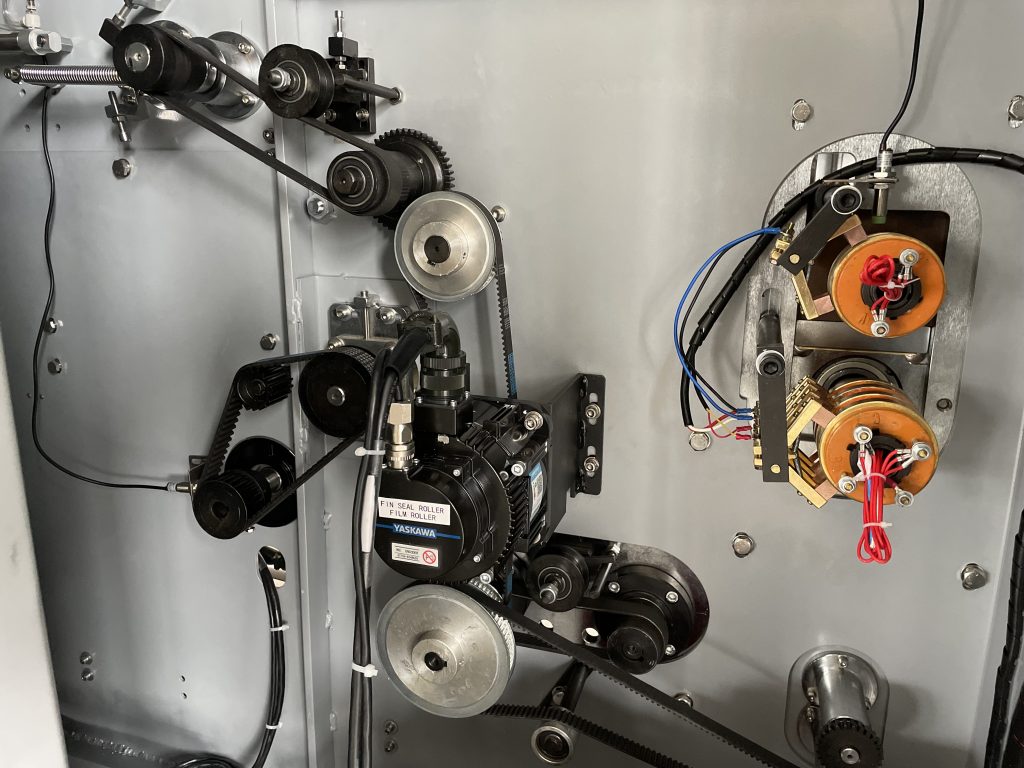

3. Lubricate your horizontal flow wrappers regularly

Another important aspect of machine maintenance is to regularly oil and grease your flow wrapper. This will help keep the moving parts running smoothly and prevent any binding or sticking problems.

Your machine should have a manual that outlines how often you need to oil your machine, but as a general rule you should do it at least once a month, but if you notice anything starting to squeak or stick, you may need to do it more often.

4. Pay close attention to the wear and tear of your horizontal flow wrappers

Over time, all machines will begin to show signs of wear and tear. It’s important to check your flow wrapper regularly for any loose bolts or screws, frayed wires, or cracks in the housing.

If you see any damage, it is best to contact your machine supplier immediately and be sure to repair it as soon as possible under their guidance.

If you repair it yourself, the supplier may say it is your own fault if problems arise later, leading to unnecessary disputes.

5. Regulate your horizontal flow wrapper on time

Maintaining your flow wrapping machine is critical to ensuring it works properly, preventing product waste, and packaging your product correctly.

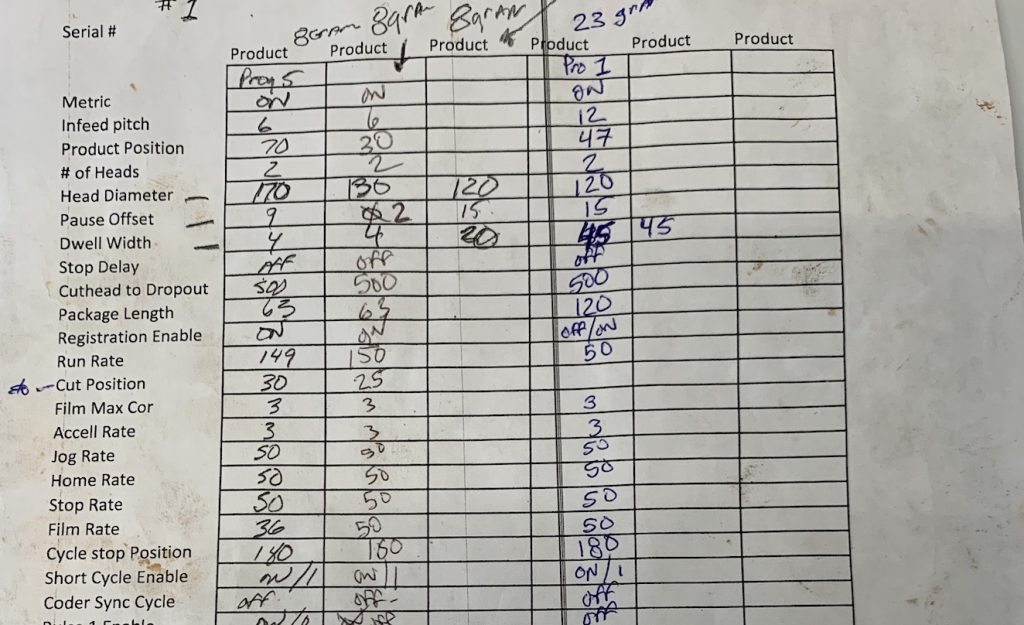

One way to do this is to calibrate your machine on a regular basis. This means checking and adjusting the machine’s settings to ensure that it is packing your products correctly.

By doing this, you can prevent product waste and make sure your horizontal flow wrapper is running smoothly.

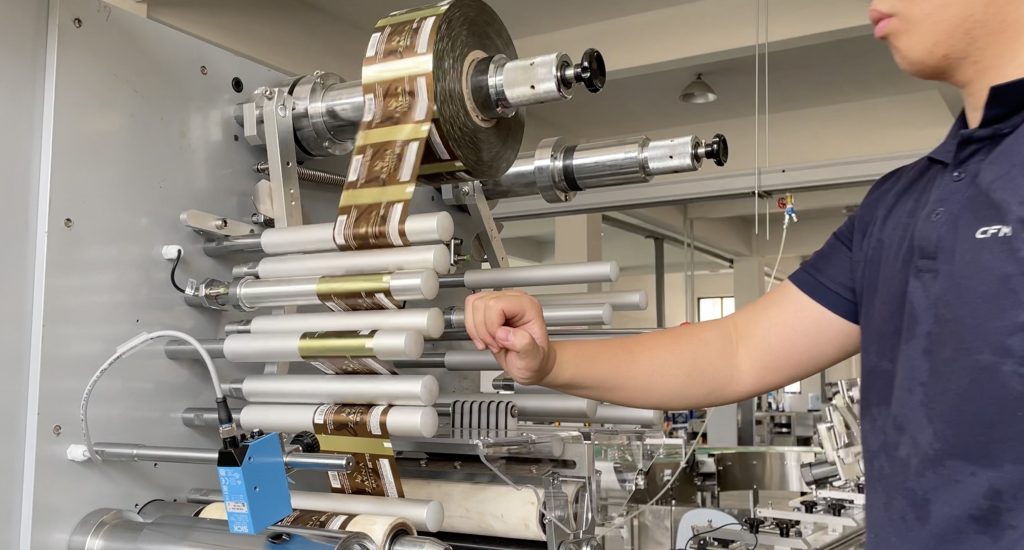

6. Pay close attention to the amount of packaging film used and film types

The amount of packaging film used needs to be carefully monitored. If it runs out and is not replenished in a timely manner, it may result in products being packaged without film, resulting in wasted products.

Be sure to refill the suitable packaging material before it is completely used up.

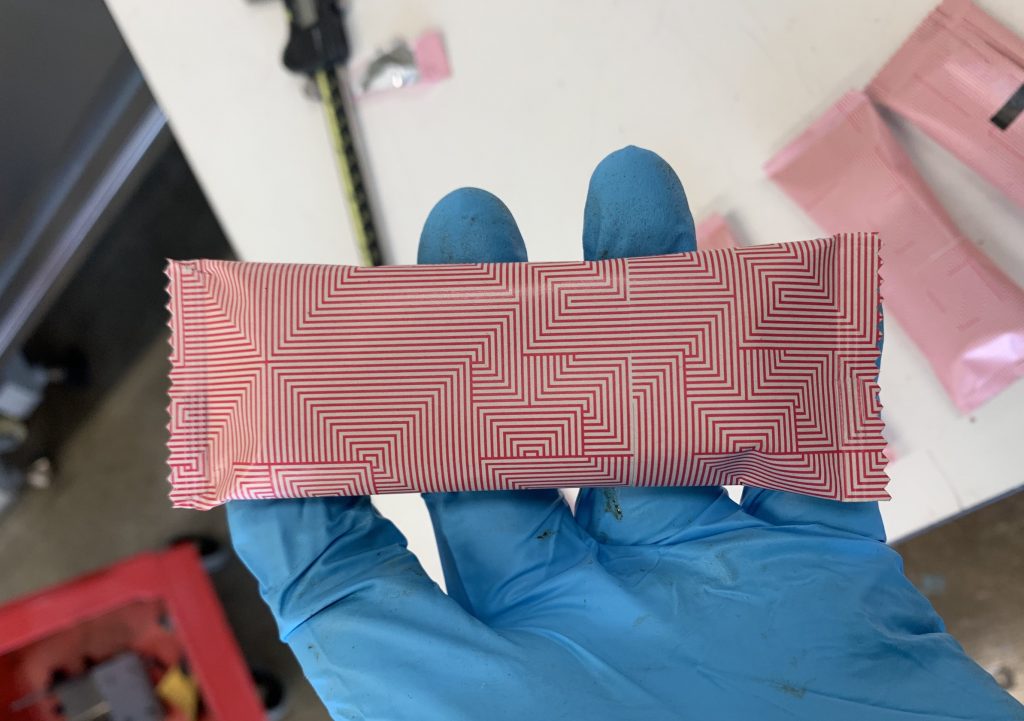

7. Regularly check the flow wrapped product to ensure it meets your quality standards

Be sure to regularly check the final machine-generated packaging to ensure that the final product meets your quality standards paragraph, because sometimes due to machine wear and tear or some imperceptible small problems.

a batch of packaging will be defective due to these problems, if the defects of this batch of packaging are not found, wait until the product is sent to the consumer to be found the problem, for your company brand is huge damage.

8. Keep records and data of all maintenance and repairs on your machines

This will help you keep track of how well your machine performs, and how stable it is.

And in the future, if there are any complex problems, engineers can also find out the relevant problems from the past maintenance and repair records, thus better-helping engineers to repair and maintain the machine.

9. If you have any questions or concerns about your machine, be sure to contact a qualified technician for help.

When it comes to maintaining and repairing your industrial equipment for your facility, it is the preferred choice to always consult with a professional to get repaired and request him for training your technician on how to do with the machine in the future.

By doing so, you can ensure that your machine is in good hands and that any potential problems will be caught early before they have a chance to cause significant damage.

Conclusion

By following these tips, you can help keep your flow wrapping machine in good working order for many years to come. Line.

If you have any questions about maintaining your machine, please contact us and we will be happy to answer them for you.