C-F Series Flow Wrapper Guide Page

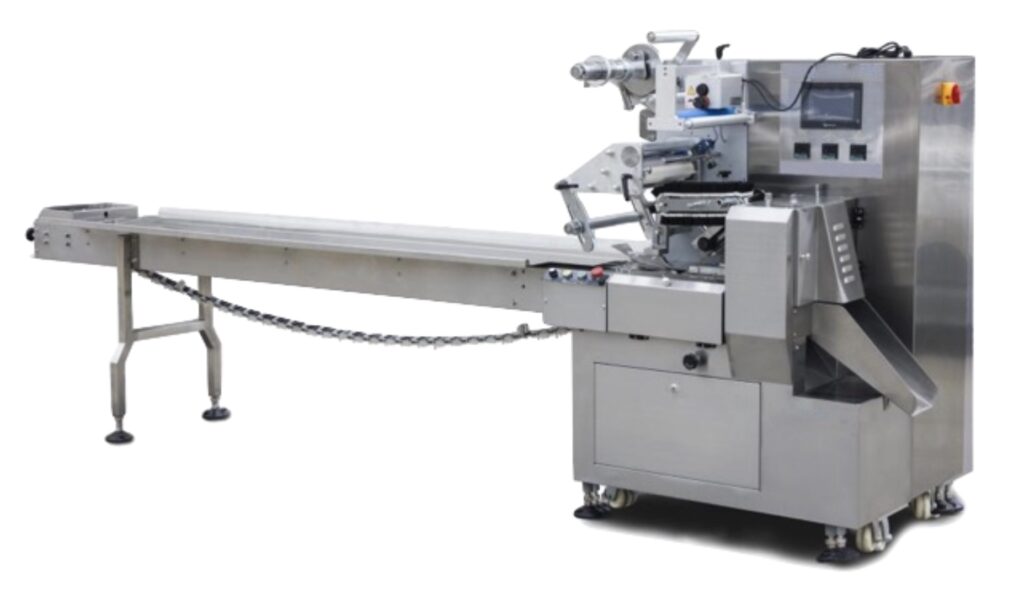

Getting to know flow wrapper and understand how to pick your best fit flow wrapper

FAQ For Flow Wrapper

A flow wrapper is a machine used for packaging products. Imagine a small pusher pin carrying items forward. As each item moves along, a continuous sheet of packaging material unrolls from a roll. This material then wraps around the item, forming a tube.

Next, the machine seals this tube along its length, right behind the product, ensuring the item is fully enclosed.

Finally, the ends of this tube are sealed and cut, creating individual packages. This process is very efficient, ideal for wrapping a large number of items quickly. Common examples of products packaged this way include candy bars, chocolates, and candies or gummies.

Flow wrappers are popular for packaging products for several key reasons:

Speed and Efficiency: Flow wrappers can package products much faster than manual packaging. This speed means more products are packaged in less time, boosting production rates.

Consistency: Every package is wrapped uniformly, giving a professional look. This consistency is vital for brand image and customer trust.

Flexibility: These machines can handle a variety of products and packaging materials. Whether it’s food, electronics, or personal care items, flow wrappers adapt easily.

Cost-Effective: By automating the packaging process, flow wrappers reduce labor costs. They also use packaging material efficiently, cutting down on waste.

Protection and Shelf Life: They provide a tight seal, protecting products from contamination and extending shelf life. This is especially important for food products.

Compact and User-Friendly: Despite their capability, flow wrappers are relatively compact and easy to operate, making them suitable for many different production environments.

In summary, flow wrappers are a go-to solution for businesses looking to enhance their packaging process in terms of efficiency, consistency, and cost-effectiveness, all while ensuring product quality and appeal.

FAQ For Flow Wrapper

A flow wrapper is a machine used for packaging products. Imagine a small pusher pin carrying items forward. As each item moves along, a continuous sheet of packaging material unrolls from a roll. This material then wraps around the item, forming a tube.

Next, the machine seals this tube along its length, right behind the product, ensuring the item is fully enclosed.

Finally, the ends of this tube are sealed and cut, creating individual packages. This process is very efficient, ideal for wrapping a large number of items quickly. Common examples of products packaged this way include candy bars, chocolates, and candies or gummies.

Flow wrappers are popular for packaging products for several key reasons:

Speed and Efficiency: Flow wrappers can package products much faster than manual packaging. This speed means more products are packaged in less time, boosting production rates.

Consistency: Every package is wrapped uniformly, giving a professional look. This consistency is vital for brand image and customer trust.

Flexibility: These machines can handle a variety of products and packaging materials. Whether it’s food, electronics, or personal care items, flow wrappers adapt easily.

Cost-Effective: By automating the packaging process, flow wrappers reduce labor costs. They also use packaging material efficiently, cutting down on waste.

Protection and Shelf Life: They provide a tight seal, protecting products from contamination and extending shelf life. This is especially important for food products.

Compact and User-Friendly: Despite their capability, flow wrappers are relatively compact and easy to operate, making them suitable for many different production environments.

In summary, flow wrappers are a go-to solution for businesses looking to enhance their packaging process in terms of efficiency, consistency, and cost-effectiveness, all while ensuring product quality and appeal.

FAQ For Confectionery Manufacturers

Flow wrappers are incredibly versatile and can package a wide range of confectionery products, including chocolates, candies, bars, and even delicate items like truffles. The adjustable settings allow for handling various sizes and shapes with ease.

The tight and secure wrapping provided by flow wrappers helps seal in freshness and protect against environmental factors like moisture and air. This helps in preserving the taste and quality of the confectionery products for longer periods.

Flow wrappers are known for their high-speed packaging capabilities. Depending on the model and product size, they can wrap hundreds items per min, significantly boosting production efficiency.

Yes, flow wrappers are adaptable to various packaging materials including foils, films, and paper. They also support custom designs and printing, allowing for brand-specific packaging styles.

Flow wrappers are equipped with precise temperature control and pressure settings to ensure consistent and reliable sealing. This means each package is securely closed and has a uniform appearance.

Regular cleaning and occasional part replacements are typically all that’s required. Most modern flow wrappers are designed for easy access and maintenance, minimizing downtime.

Modern flow wrappers often feature user-friendly interfaces and quick changeover capabilities, allowing for relatively easy switches between different products or packaging designs with minimal downtime.

The initial investment can vary based on the machine’s capabilities and features. However, the ROI is generally high due to increased production speed, reduced labor costs, and material efficiency.

Generally, a clean and dry environment is recommended. Extreme temperatures and humidity can affect machine performance and product quality, so a controlled environment is ideal.

CFM Pack provide comprehensive training and ongoing support for our flow wrappers, ensuring that your team can operate the machine effectively and troubleshoot any issues.

FAQ For Confectionery Manufacturers

Flow wrappers are incredibly versatile and can package a wide range of confectionery products, including chocolates, candies, bars, and even delicate items like truffles. The adjustable settings allow for handling various sizes and shapes with ease.

The tight and secure wrapping provided by flow wrappers helps seal in freshness and protect against environmental factors like moisture and air. This helps in preserving the taste and quality of the confectionery products for longer periods.

Flow wrappers are known for their high-speed packaging capabilities. Depending on the model and product size, they can wrap hundreds items per min, significantly boosting production efficiency.

Yes, flow wrappers are adaptable to various packaging materials including foils, films, and paper. They also support custom designs and printing, allowing for brand-specific packaging styles.

Flow wrappers are equipped with precise temperature control and pressure settings to ensure consistent and reliable sealing. This means each package is securely closed and has a uniform appearance.

Regular cleaning and occasional part replacements are typically all that’s required. Most modern flow wrappers are designed for easy access and maintenance, minimizing downtime.

Modern flow wrappers often feature user-friendly interfaces and quick changeover capabilities, allowing for relatively easy switches between different products or packaging designs with minimal downtime.

The initial investment can vary based on the machine’s capabilities and features. However, the ROI is generally high due to increased production speed, reduced labor costs, and material efficiency.

Generally, a clean and dry environment is recommended. Extreme temperatures and humidity can affect machine performance and product quality, so a controlled environment is ideal.

CFM Pack provide comprehensive training and ongoing support for our flow wrappers, ensuring that your team can operate the machine effectively and troubleshoot any issues.

Pick Your Best Fit Flow Wrapper

C-F Series Entry-Level Flow Wrapper

C-F Series Inverted Flow Wrapper

C-F Series Fully Automated Flow Wrapper

Selection Tutorial

On-Site Working Videos

Comprehensive Services

Consultation Services

Before you make a purchase, our experts will help you identify the perfect flow wrapper for your specific needs. We take into consideration your product types, production volume, and operational requirements.

Installation and Setup

Our team will handle the installation process, ensuring that your flow wrapper is set up correctly and integrated smoothly into your production line.

Training Programs

We offer extensive training for your staff to ensure they are proficient in operating the machinery. This includes handling, maintenance, and safety protocols.

Maintenance and Support

Our service agreements include regular maintenance checks and on-call support to troubleshoot any issues that may arise, minimizing downtime and maintaining productivity.

Spare Parts Supply

We provide a reliable supply of spare parts, ensuring that any required replacements can be delivered swiftly to keep your operations running without interruptions.

Upgrades and Enhancements

As technology advances, we provide the latest upgrades and enhancements that can be made to your flow wrapper, keeping it at the forefront of packaging technology.

"Skyrocket Your Efficiency With CFM"

At The Evolving Market, You Need A Automation Expert By Your Side, Experienced, Knowledgeable, Efficient, Honest. CFM will Be The One.